Leibniz Universität Hannover

Institut für Bauinformatik

Prof. Dr.-Ing. Volker Berkhahn

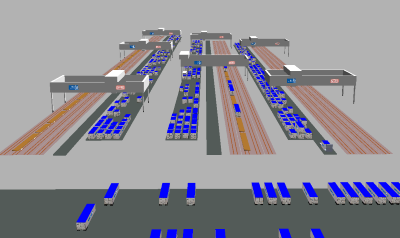

Intermodal Cargo Transshipment Terminals are hinterland facilities for transhipping cargo loading units between trucks and trains or among trains. In contrast to marshalling yards the transport of loading units at modern terminals is mostly carried out by conveyance systems like gantry cranes that span over several tracks. On larger terminals additional conveyance systems may assist the gantry cranes to reduce longitudinal crane movement.

The operation of a terminal is usually coordinated by a dispatcher, who – based on his experience – decides in which manner the loading units will be transshiped on the terminal. Nowadays, the results of simulating terminal operation are considered an important part during the planning process of the construction or extension of terminals.

Together with industrial partners and research institutions in Germany and abroad, the proposed concepts and methods are implemented and validated in diverse applications in the built and in the natural environment, including, for example, autonomous monitoring (i) of wind turbines, supporting a sustainable monitoring-based life-cycle management, (ii) of slope conditions, enabling early warnings in case of hazardous slope movements or suspected landslides, or (iii) of soil parameters, allowing for intelligent irrigation control and significantly reduced freshwater consumptions in agricultural ecosystems.

These simulations are very important to determine the right scaling and layout that fulfil the performance requirements of the terminal. Even the decisions of an experienced dispatcher might not always be the best under all relevant aspects. Thus, the theoretical manageable maximum workload at the terminal has to be determined. In a final step it has to be ensure that the maximum workload and the optimisation objectives are reached in practice.

Since 2009 the Institut für Bauinformatik deals with the simulation of Intermodal Cargo Transshipment Terminals in cooperation with the planners and operators to create a framework that meet these requirements. The developed algorithms have the ability to react just in time on changes in constraints, e.g. train delays or crane malfunctions. Only this feature guarantees that the results of the simulation and optimisation are close to reality.